Bridgestone Uses Retread Technology to Develop Ground-Breaking Truck and Bus Tire Manufacturing TechnologyResults in Both Significant Resource Savings and Enhanced Fuel Efficiency

TOKYO (September 7, 2012)—Bridgestone Corporation today announced that it has developed a new truck and bus tire manufacturing technology that will result in both significant resource conservation and enhanced fuel efficiency. The new technology is called TRISAVER, a reference to the three types of savings it enables: savings of costs, resources and CO2 emissions.

Since acquiring Bandag, Incorporated in 2007, Bridgestone has been in development of a global solutions business using retread tires and Bandag's retread technology. While new tires are manufactured by vulcanizing*1 all the materials at once, retread tire manufacturing bonds together a separate and previously vulcanized casing (the original body of the tire that remains once its initial tread life has been used) and the tread (the rubber component of the tire that makes contact with the road). Focusing on this basic difference in manufacturing methods, Bridgestone has discovered that overall performance of the tire can be improved by manufacturing the casing and tread through a process that is optimal for each component.

Bridgestone's TRISAVER technology uses this innovative manufacturing method, as well as a revolutionary new compound in both the casing and the tread. This new technology greatly reduces rolling resistance compared to conventional tires, and at the same time enhances durability, thereby potentially increasing the number of times the tire can be retreaded.

This revolutionary new technology offers customer value through cost savings, since greater durability means the tire can be retreaded more times, and improved fuel efficiency through lower rolling resistance. At the same time, the technology benefits the environment by using resources more effectively and reducing CO2 emissions.

With plans to market this new technology in the near future, Bridgestone is in the process of conducting road trials and analyzing product marketability.

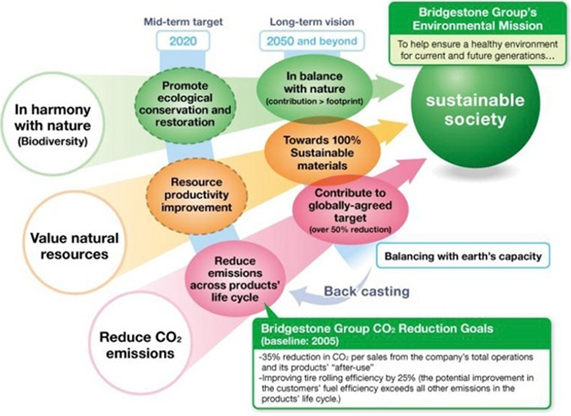

The Bridgestone Group has established the long-term environmental goals of using 100% sustainable materials*2 and contributing to reaching the globally-agreed target for reducing greenhouse gas emissions*3 (CO2 emissions reduction of at least 50%) by 2050.

*1: A process of applying heat and pressure to rubber in order to increase its elasticity and strength

*2: The Bridgestone Group defines "sustainable materials" as "materials that are not expected to become depleted as a result of consumption, as opposed to fossil resources and other limited resources."

Examples: Recycled materials, materials derived from biomass, base tires that reuse end-of-life tires, etc.

Examples: Recycled materials, materials derived from biomass, base tires that reuse end-of-life tires, etc.

*3: At its summit in Toyako, Hokkaido in July 2008, the Group of Eight (G8) countries agreed to work to reduce worldwide greenhouse gas emissions by at least 50% by the year 2050. This shared target, which was accepted at the same year's Major Economies Meeting on preventing global warming (including developed countries plus China and India among other countries), is used as the globally agreed target.

[Reference]

"TRISAVER" is one initiative whereby the Bridgestone Group seeks to achieve two parts of its long-term environmental goals: using 100% sustainable materials and contributing to reaching the globally-agreed target for reducing greenhouse gas emissions (CO2 emissions reduction of at least 50%).

About Bridgestone Corporation:

Bridgestone Corporation, headquartered in Tokyo, is the world’s largest tire and rubber company. In addition to tires for use in a wide variety of applications, it also manufactures a broad range of diversified products, which include industrial rubber and chemical products and sporting goods. Its products are sold in over 150 nations and territories around the world.

Bridgestone Corporation, headquartered in Tokyo, is the world’s largest tire and rubber company. In addition to tires for use in a wide variety of applications, it also manufactures a broad range of diversified products, which include industrial rubber and chemical products and sporting goods. Its products are sold in over 150 nations and territories around the world.