- Home

- Products

- Aircraft Tires

- Products

- Basic Structure

Products

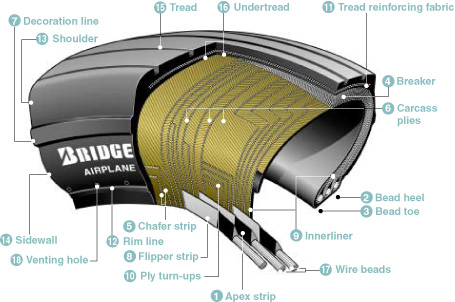

Basic Structure - Bias Tires

| Basic Structure | |

|

|

| Tire Markings | |

|

|

| Tire Terminology | |

| 1. Apex strip: A triangular piece of stiff rubber which is fitted onto the bead core to taper the rigid bead into the flexible body plies in the sidewall. 2. Bead heel: Outer edge of the bead. 3. Bead toe: Inner edge of the bead. 4. Breaker: Breakers are fabric plies placed directly on the upper-most ply beneath the tread rubber. They disperse stress throughout the tire. This breaker is utilized in a limited number of Bridgestone aircraft tires. 5. Chafer strip: Reinforces the beads and protects the cord body-plies from damage from rim friction or from damage when replacing the rim. 6. Carcass plies: Each nylon ply is held by wire beads across the tire to keep the tensile strength at the proper level, and is folded to the side of the sidewall. Each ply is provided with cushion rubber to reduce shearing force produced between the cords of the tire when it is deformed. Multiple coated-nylon cords are crossed alternately on the bias to make the carcass. 7. Decoration line: A projecting, embossed line molded between the shoulder and sidewall of a tire. Its purpose is for decoration only. 8. Flipper strip: A strip of material which is wrapped around the bead bundle and filler to add support and help taper the assembly into the sidewall. 9. Innerliner: A sheet of special rubber laminated to the inside of the first casing ply of the tubeless tire so as to ensure retention of pressure when the tire is inflated. 10. Ply turn-ups: The turned-up ends of plies around the bead. Other plies lock the ends into place. 11. Tread reinforcing fabric: Nylon cord plies located in the tread between the tread groove and the outer ply of the carcass which reduce tread squirm and increase stability for high speed operations. 12. Rim line: This line is provided near the beads to allow inspection of how the tire fits with the rim. 13. Shoulder: The area on the side of the tire between the sidewall and the tread. 14. Sidewall: The side area of the tire located between the buttress and the beads. Composed of rubber, it protects the carcass from damage. 15. Tread: A layer of rubber on the outer circumference of a tire, its major functions are to protect the casing from cuts, withstand high speed during take-off and landing, provide traction, resist wear, provide durability under a wide range of temperatures and to ensure stability (in particular, the effective discharge of water on wet runways). The tread compound is designed to suit a wide range of operations. 16. Undertread: A rubber layer provided for use in retreading the tire and which provides adhesion of tread to the cord body. Bridgestone makes this rubber layer thick enough to ensure a high number of retreads. 17. Wire beads: Constructed of steel wire encased in rubber, they help to maintain the shape of the tire and keep it securely fixed to the rim. The wire beads are wrapped with fabric. 18. Venting hole: The hole through which gas is vented from inside the carcass plies. * Balance marker A balance marker, consisting of a red dot, is affixed on the sidewall of the tire immediately above the bead to indicate the lightweight point of the tire. > Basic Structure - Radial Tires |